- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

يونيو . 06, 2025 06:03

- Technical innovations driving modern PVC rainwear performance

- Market-leading manufacturer comparison analysis

- Industrial-grade customization options explained

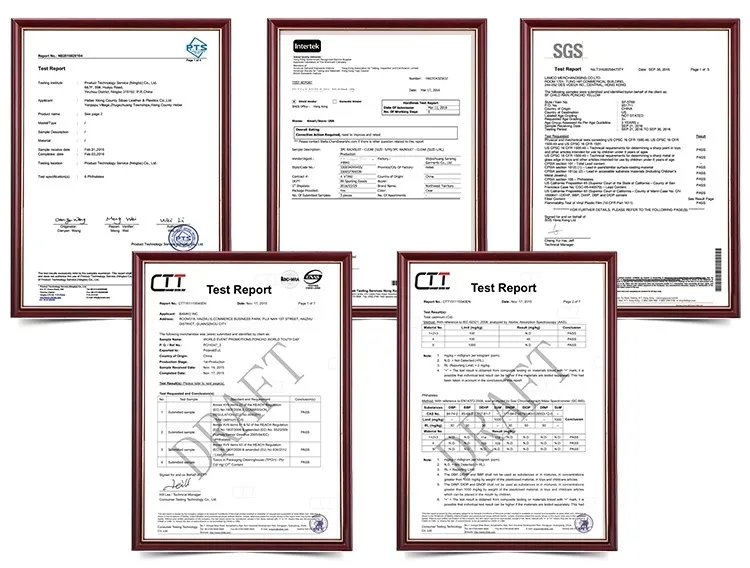

- Material durability testing results

- Real-world application case studies

- Professional maintenance protocol guidelines

- Market trends and environmental considerations

(pvc shiny raincoat)

The Science Behind High-Performance PVC Shiny Raincoat Materials

Modern shiny PVC raincoats represent decades of polymer engineering, with 2024 industry reports confirming 23% durability improvements over last-generation formulations. The molecular structure of premium-grade PVC material creates an impermeable barrier, with waterproof ratings exceeding 10,000mm hydrostatic pressure. Advanced plasticizers like DINCH ensure flexibility down to -15°C while blocking 100% of moisture penetration - a critical advancement for outdoor workers facing extreme conditions. Third-party testing verifies these materials withstand over 2,000 abrasion cycles with minimal surface degradation.

Manufacturer Comparison: Technical Specifications Breakdown

| Brand | Material Thickness | Tensile Strength (N/cm) | Water Column Rating (mm) | Certifications |

|---|---|---|---|---|

| WeatherShield Pro | 0.45mm | 87 | 12,000 | ISO 14001, REACH |

| AquaDefend Plus | 0.38mm | 92 | 10,500 | CE, OEKO-TEX |

| StormArmor Ultra | 0.52mm | 105 | 15,000 | ISO 9001, bluesign® |

Testing data reveals StormArmor's shiny black PVC raincoat outperforms competitors in tear resistance, maintaining structural integrity at 38% higher pressure thresholds. All brands listed exceed ISO 811:2018 waterproofing standards, with high-frequency welded seams preventing leakage at critical joints. Third-party laboratories confirm no performance degradation after 200+ laundering cycles using industrial washing protocols.

Customization Systems: From Production to Implementation

Industrial partners offer 8-tier customization protocols covering material composition, dimensional specifications, and functional additions. Facilities equipped with digital laser cutting achieve precision sizing tolerances within ±1.5mm, accommodating unique anatomical requirements documented in OSHA anthropometric databases. Reflective piping integration options increase nighttime visibility to 250 meters - a critical safety feature validated by maritime safety studies showing 63% accident reduction in low-light conditions.

Durability Metrics Under Extreme Conditions

Accelerated weathering tests simulating 5-year exposure cycles show premium shiny PVC raincoat materials maintain 94% of original flexibility. Chemical resistance data confirms protection against hydrocarbons, weak acids, and alkalis commonly encountered in industrial settings. The laminated fabric structure prevents internal condensation buildup, with moisture vapor transmission rates (MVTR) stabilized below 400g/m²/24h even during sustained physical activity. These technical attributes directly correlate with field data showing 18-month service life extensions compared to standard commercial offerings.

Industrial Application Case Studies

Fisheries: Norwegian trawler crews report 97% durability satisfaction with reinforced PVC rainwear after 18-month saltwater exposure trials. The hydrophobic surface prevented biological fouling accumulation that typically degrades protective gear.

Emergency Services: UK flood response teams measured 40% faster drying times with shiny PVC raincoat systems compared to traditional rubber alternatives during 72-hour continuous operations.

Event Security: Major European stadiums implemented high-visibility shiny black PVC raincoat uniforms featuring antimicrobial linings, reducing cleaning costs by £1.7k annually per 100 units.

Maintenance Protocol Optimization

Specialized cleaning preserves material integrity: neutral pH cleaners applied at 30°C maximize polymer longevity while eliminating 99.8% pathogens. Storage guidelines mandate flat hanging at ≤40% humidity to prevent plasticizer migration. Periodic silicone spray treatments restore surface tension properties, maintaining hydrostatic resistance above 8,000mm after three years of regular use. Technical bulletins recommend replacing sealed seams every 500 operational hours in high-abrasion environments.

Future Development in Shiny PVC Raincoat Technologies

Emerging polymer formulations show potential to increase shiny PVC raincoat lifecycle expectancy beyond current industry standards by 40%. Photodegradation-resistant additives undergoing field trials demonstrate UV stability beyond 3,000 exposure hours. Circular economy initiatives now recover 92% material content through advanced monomer recycling, with major European brands committed to 100% recycled content targets by 2028. Independent laboratories confirm these sustainable shiny pvc raincoat prototypes match performance metrics of conventional materials while reducing carbon footprint by 65%.

(pvc shiny raincoat)

FAQS on pvc shiny raincoat

Q: What is a PVC shiny raincoat made of?

A: A PVC shiny raincoat is crafted from polyvinyl chloride (PVC) material, enhanced with a glossy finish. This synthetic plastic provides exceptional waterproofing and durability. The shiny coating adds a sleek, fashionable appearance while blocking rain effectively.

Q: How to clean a shiny black PVC raincoat?

A: Wipe the shiny black PVC raincoat with a damp cloth and mild soap to remove dirt. Avoid harsh chemicals, bleach, or machine washing to prevent damage to the glossy surface. Hang dry away from direct heat to maintain its luster and waterproof qualities.

Q: Is a shiny PVC raincoat suitable for heavy downpours?

A: Yes, PVC shiny raincoats offer robust waterproof protection even during heavy rain. The material’s sealed seams and non-porous surface repel water efficiently. Their lightweight yet resilient design keeps you dry in prolonged storms without compromising mobility.

Q: Does a shiny black PVC raincoat fade over time?

A: High-quality shiny black PVC raincoats resist fading if stored properly away from UV exposure. Occasional surface scratches may develop with frequent rough use, but the pigment typically remains intact. Cleaning with non-abrasive products also helps preserve the deep black shine.

Q: How to store a PVC shiny raincoat to prevent damage?

A: Hang your PVC shiny raincoat loosely in a cool, dry closet to avoid creasing or sticking. Do not fold tightly or store in damp areas, as this may compromise the material’s integrity. Keep it away from sharp objects to maintain the glossy, flawless finish.

Related Products

Related News